Keeping a classic car clean and free of excess grease are fundamental steps that need to be taken ar every stage of its restoration and maintenance.

>Decades of corrosion, dust, oil residue and road grime if allowed to accumulate on body shells, chassis, engines and various mechanical components will take very little time to obscure faults and compromise the quality of repairs and refinishing.

To prevent this happening pneumatically powered cleaning, blowing, and degreasing tools are widely used in professional restoration workshops, providing powerful, reliable, safe answers to these issues, exceptionally well suited to the harshest workshop environments.

An indispensable tool in keeping a classic car clean is the air blow gun. Despite being of a very simple design, the air blow gun plays a crucial role in daily workshop operations.

Used to clear debris from panels before sanding or painting, dry components after washing, remove swarf from drilled holes and clean inaccessible cavities, pneumatic blow guns deliver a high-velocity, controllable airflow without generating heat, a factor that makes them safe for use on the most delicate of components including electrical connectors and freshly cleaned metal surfaces. Because of their lightweight construction, air blow guns allow constant use throughout the day with minimal fatigue to its operator.

Complementing the air blow gun is the air vacuum gun, providing a practical solution for debris removal. Rather than dispersing dust into the workshop air, vacuum guns gathers all manners of dirt, metal filings, and sanding residue directly into its integral container, an asset that is particularly advantageous when working inside confines spaces as such as enclosed chassis sections, engine bays, vehicle interiors, where cleanliness and visibility are essential.

Designed to deal with the toughest of situations, pneumatic vacuum guns are robust and resistant to clogging, making them ideal for removing dry contaminants without relying on electric motors or filters that may struggle in dusty restoration environments.

For more intensive cleaning tasks, the pneumatic parts cleaning gun is an indispensable tool for mechanical restoration and maintenance work, thanks to its ability to atomise cleaning fluids or solvents using compressed air, allowing grease, oil, and carbon deposits to be removed efficiently from carburettors engine components, gearboxes and suspension parts.

Pneumatic parts cleaning guns offer excellent control over fluid flow and spray pattern, enabling targeted cleaning while minimising waste. Because they rely on air rather than electric pumps, they are well suited to prolonged use and are inherently safer around flammable cleaning agents commonly used in restoration workshops.

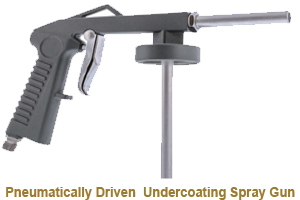

One of the most demanding cleaning tasks in classic car work is protecting and sealing the underside of the vehicle, where corrosion often begins. Specifically designed for applying underseal, cavity wax, stone-chip coatings, and rust inhibitors, pneumatically powered underbody spray guns provide consistent pressure as well as even material distribution, ensuring thorough coverage of chassis rails, floor pans, wheel arches, and box sections. The ability of the pneumatically powered underbody spray gun to atomise thick protective coatings makes them invaluable for long-term corrosion prevention on restored vehicles.

A key advantage of all pneumatic cleaning and degreasing tools is their durability. Restoration workshops are dusty, oily, and often damp environments—conditions that can be hostile to electric motors and electronics.

Safety is another significant benefit. Pneumatic tools do not generate electrical sparks and produce minimal heat, reducing fire risk when working with solvents, fuels, and vapours. This makes them particularly suitable for engine bay cleaning, fuel system maintenance, and underbody work, where flammable residues may be present.

From a workflow perspective, pneumatically powered cleaning tools integrate seamlessly into a professional workshop environment. A central compressed air system can support multiple workstations, allowing cleaning, drying, degreasing, and coating operations to take place simultaneously. This efficiency is especially valuable in large-scale restorations, where time management and consistent quality are critical.

Keeping a classic car clean and free of excess grease are fundamental steps that need to be taken ar every stage of its restoration and maintenance.

>Decades of corrosion, dust, oil residue and road grime if allowed to accumulate on body shells, chassis, engines and various mechanical components will take very little time to obscure faults and compromise the quality of repairs and refinishing.

To prevent this happening pneumatically powered cleaning, blowing, and degreasing tools are widely used in professional restoration workshops, providing powerful, reliable, safe answers to these issues, exceptionally well suited to the harshest workshop environments.

An indispensable tool in keeping a classic car clean is the air blow gun. Despite being of a very simple design, the air blow gun plays a crucial role in daily workshop operations.

Used to clear debris from panels before sanding or painting, dry components after washing, remove swarf from drilled holes and clean inaccessible cavities, pneumatic blow guns deliver a high-velocity, controllable airflow without generating heat, a factor that makes them safe for use on the most delicate of components including electrical connectors and freshly cleaned metal surfaces. Because of their lightweight construction, air blow guns allow constant use throughout the day with minimal fatigue to its operator.

Keeping a classic car clean and free of excess grease are fundamental steps that need to be taken ar every stage of its restoration and maintenance.

>Decades of corrosion, dust, oil residue and road grime if allowed to accumulate on body shells, chassis, engines and various mechanical components will take very little time to obscure faults and compromise the quality of repairs and refinishing.

To prevent this happening pneumatically powered cleaning, blowing, and degreasing tools are widely used in professional restoration workshops, providing powerful, reliable, safe answers to these issues, exceptionally well suited to the harshest workshop environments.

An indispensable tool in keeping a classic car clean is the air blow gun. Despite being of a very simple design, the air blow gun plays a crucial role in daily workshop operations.

Used to clear debris from panels before sanding or painting, dry components after washing, remove swarf from drilled holes and clean inaccessible cavities, pneumatic blow guns deliver a high-velocity, controllable airflow without generating heat, a factor that makes them safe for use on the most delicate of components including electrical connectors and freshly cleaned metal surfaces. Because of their lightweight construction, air blow guns allow constant use throughout the day with minimal fatigue to its operator.

Complementing the air blow gun is the air vacuum gun, providing a practical solution for debris removal. Rather than dispersing dust into the workshop air, vacuum guns gathers all manners of dirt, metal filings, and sanding residue directly into its integral container, an asset that is particularly advantageous when working inside confines spaces as such as enclosed chassis sections, engine bays, vehicle interiors, where cleanliness and visibility are essential.

Designed to deal with the toughest of situations, pneumatic vacuum guns are robust and resistant to clogging, making them ideal for removing dry contaminants without relying on electric motors or filters that may struggle in dusty restoration environments.

Complementing the air blow gun is the air vacuum gun, providing a practical solution for debris removal. Rather than dispersing dust into the workshop air, vacuum guns gathers all manners of dirt, metal filings, and sanding residue directly into its integral container, an asset that is particularly advantageous when working inside confines spaces as such as enclosed chassis sections, engine bays, vehicle interiors, where cleanliness and visibility are essential.

Designed to deal with the toughest of situations, pneumatic vacuum guns are robust and resistant to clogging, making them ideal for removing dry contaminants without relying on electric motors or filters that may struggle in dusty restoration environments.

For more intensive cleaning tasks, the pneumatic parts cleaning gun is an indispensable tool for mechanical restoration and maintenance work, thanks to its ability to atomise cleaning fluids or solvents using compressed air, allowing grease, oil, and carbon deposits to be removed efficiently from carburettors engine components, gearboxes and suspension parts.

Pneumatic parts cleaning guns offer excellent control over fluid flow and spray pattern, enabling targeted cleaning while minimising waste. Because they rely on air rather than electric pumps, they are well suited to prolonged use and are inherently safer around flammable cleaning agents commonly used in restoration workshops.

For more intensive cleaning tasks, the pneumatic parts cleaning gun is an indispensable tool for mechanical restoration and maintenance work, thanks to its ability to atomise cleaning fluids or solvents using compressed air, allowing grease, oil, and carbon deposits to be removed efficiently from carburettors engine components, gearboxes and suspension parts.

Pneumatic parts cleaning guns offer excellent control over fluid flow and spray pattern, enabling targeted cleaning while minimising waste. Because they rely on air rather than electric pumps, they are well suited to prolonged use and are inherently safer around flammable cleaning agents commonly used in restoration workshops.

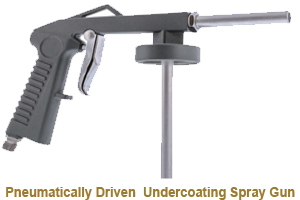

One of the most demanding cleaning tasks in classic car work is protecting and sealing the underside of the vehicle, where corrosion often begins. Specifically designed for applying underseal, cavity wax, stone-chip coatings, and rust inhibitors, pneumatically powered underbody spray guns provide consistent pressure as well as even material distribution, ensuring thorough coverage of chassis rails, floor pans, wheel arches, and box sections. The ability of the pneumatically powered underbody spray gun to atomise thick protective coatings makes them invaluable for long-term corrosion prevention on restored vehicles.

A key advantage of all pneumatic cleaning and degreasing tools is their durability. Restoration workshops are dusty, oily, and often damp environments—conditions that can be hostile to electric motors and electronics.

Safety is another significant benefit. Pneumatic tools do not generate electrical sparks and produce minimal heat, reducing fire risk when working with solvents, fuels, and vapours. This makes them particularly suitable for engine bay cleaning, fuel system maintenance, and underbody work, where flammable residues may be present.

From a workflow perspective, pneumatically powered cleaning tools integrate seamlessly into a professional workshop environment. A central compressed air system can support multiple workstations, allowing cleaning, drying, degreasing, and coating operations to take place simultaneously. This efficiency is especially valuable in large-scale restorations, where time management and consistent quality are critical.

One of the most demanding cleaning tasks in classic car work is protecting and sealing the underside of the vehicle, where corrosion often begins. Specifically designed for applying underseal, cavity wax, stone-chip coatings, and rust inhibitors, pneumatically powered underbody spray guns provide consistent pressure as well as even material distribution, ensuring thorough coverage of chassis rails, floor pans, wheel arches, and box sections. The ability of the pneumatically powered underbody spray gun to atomise thick protective coatings makes them invaluable for long-term corrosion prevention on restored vehicles.

A key advantage of all pneumatic cleaning and degreasing tools is their durability. Restoration workshops are dusty, oily, and often damp environments—conditions that can be hostile to electric motors and electronics.

Safety is another significant benefit. Pneumatic tools do not generate electrical sparks and produce minimal heat, reducing fire risk when working with solvents, fuels, and vapours. This makes them particularly suitable for engine bay cleaning, fuel system maintenance, and underbody work, where flammable residues may be present.

From a workflow perspective, pneumatically powered cleaning tools integrate seamlessly into a professional workshop environment. A central compressed air system can support multiple workstations, allowing cleaning, drying, degreasing, and coating operations to take place simultaneously. This efficiency is especially valuable in large-scale restorations, where time management and consistent quality are critical.