Most restoration projectors are usually inclined to leave the vehicle's paintwork till the last. In many cases, the original paintwork will have been partially removed during the bodywork phase through sandblasting or acid dipping.

Most restoration projectors are usually inclined to leave the vehicle's paintwork till the last. In many cases, the original paintwork will have been partially removed during the bodywork phase through sandblasting or acid dipping.

If the vehicle has some, if not all, its paintwork intact, the restorer will be faced with the daunting task of removing the existing paint- never enjoyable but something that has to be done. The paint surface may be unstable, and difficult for the paint sprayers to apply paint on top of it.

There are three ways to remove unwanted paint in the workshop:

The first option, but not always the favourite, is to use power tools to remove the paint. Professional painters veer towards the dual action (DA) sander for this type of work.

The first option, but not always the favourite, is to use power tools to remove the paint. Professional painters veer towards the dual action (DA) sander for this type of work. Either air or electrically powered, the DA sander can be fitted with disks as coarse as 36 grit to get started, though the grit level will soon switch to between 80 or 120 grit, with 180 grit discs being used to complete the process, leaving the bodywork in a condition where it can be primed,

The lower the grit number translates to a coarser abrasive level, ideal for scraping off paint much quicker. The higher the grit number, the finer the abrasive, creating a smoother surface finish.

The lower the grit number translates to a coarser abrasive level, ideal for scraping off paint much quicker. The higher the grit number, the finer the abrasive, creating a smoother surface finish. DA sanders are heavy pieces of professional equipment, expensive to buy and hard to handle. That's the reason why most semi-professional restorers who want to handle the job in house invest in an electrically powered orbital sander.

Less powerful and considerably smaller than the dual action (DA) sander, the orbital sander lends itself very well to more compact areas but will take far too much time and energy to remove an entire coat of paint.

![]()

Another mechanical option that can do the job of removing a section of paint is the angle-grinder.

Fitted with a 60 or 80 disc backed up with a flexible pad, the operator has to make sure that they handle the angle grinder with caution, lightly stroking it against the panels or else severe damage will be caused.

Working with angle grinders means creating mountains of dust, meaning that masks must be worn at all times.

Grinding metal also gives off sparks, making wearing goggles a must.

Anyone who wants to cut corners and is brave enough to do so can permanently attach a wire wheel to the angle grinder. This combination will remove the paint, but if the operator is not careful, the damage done to the bodywork may not justify the time saved.

Anyone who wants to cut corners and is brave enough to do so can permanently attach a wire wheel to the angle grinder. This combination will remove the paint, but if the operator is not careful, the damage done to the bodywork may not justify the time saved.

While sanding remains the favourite option for removing paint on a localised basis, the use of heat is a user-friendly and effective method of removing paint.

Like every other paint removing process, applying heat and even flame has to be treated with respect and caution, especially in a closed workshop.

Apart from the risks to life and limb, restorers should be aware of the likelihood that if the heat is not adequately controlled, specific panels are liable to become irreparably warped during the heating process.

That is why it is recommended that heat treatment be applied only in pillars, wheel arches, and the tops of wings- areas that are not liable to distort. On the other hand, flat panels will bow and pop very easily if heated.

When using heat, the first sign of progress is when the paint begins to blister.

At that point, a simple paint scraper should be brought in to remove the softened paint.

Passing over the area with nylon or wire brush will add that final touch to finish the job and make it primer ready.

![]()

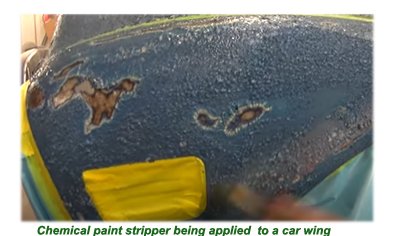

The last alternative when it comes to removing paint is the use of a chemical paint stripper.

This method is best employed when the area of paint that needs to be removed is more extensive than can be handled by sanding or heating or a few coats on the surface.

As there are toxic chemicals involved in the process, it is recommended that the panel or panels to be treated be removed for ease of operation and prevent the risk of injury or damage.

Before the material has been exposed, the floor around the work area and the bench where the job will be done should be covered with either protective paper or plastic, especially where the stripped paint will fall.

Before the material has been exposed, the floor around the work area and the bench where the job will be done should be covered with either protective paper or plastic, especially where the stripped paint will fall.

Paint stripper, which today comprises a combination of compounds, including benzyl alcohol, methyl pyrrolidone, and alkylenes, such as propylene carbonate or ethylene carbonate, is poured directly onto the panels to be treated, placed in a horizontal position.

The stripper should be spread in sufficient quantities that each layer of paint applied over the years has been removed till the bare metal is totally exposed.

The stripper should be spread in sufficient quantities that each layer of paint applied over the years has been removed till the bare metal is totally exposed.

Once all the paint has been removed, the treated panels should be wiped clean with water to remove all traces of the stripper.

Particular attention should be made to ensure that not a drop of this powerful chemical remains.

Even the slightest residue is liable to cause an adverse reaction with any paint applied in the future.

pw3