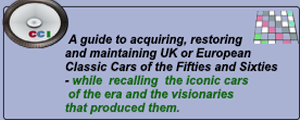

UK and European classic cars from the Fifies and Sixties almost always came fitted with individual V-belts used to drive accessories such as the fan, alternator (or dynamo), and water pump. The importance of their function meant keeping the belt in tip-top condition is essential, since if it slipped or even worse snapped the engine would fail to cool or lose its charge, or both.

A V-belt in an internal combustion engine is a type of drive belt used to transfer power from the engine’s crankshaft pulley to various auxiliary components. It gets its name from its cross-sectional shape—a trapezoid or “V”—which wedges into the pulleys for better grip. Often V-belts are confused with Timing chains, which came much later, although they came much later. Timing chains gradually replaced V-belts simply because they were much stronger and therefore, less inclined to snap.

If a timing chain slips or breaks, valve timing is lost. In most engines this will inevitably lead to catastrophic damage.

The V-belt was designed to provide mechanical power to engine accessories such as the:

Often V-belts are confused with Timing chains, which came much later, although they came much later. Timing chains gradually replaced V-belts simply because they were much stronger and therefore, less inclined to snap.

If a timing chain slips or breaks, valve timing is lost. In most engines this will inevitably lead to catastrophic damage.

The V-belt was designed to provide mechanical power to engine accessories such as the:

- Alternator (generates electricity to charge the battery and power electrical systems)

- Water pump (circulates coolant through the engine and radiator)

- Power steering pump (assists in turning the steering wheel)

- Air conditioning compressor (drives the AC system)

- Fan (in older vehicles, belt-driven radiator cooling fan)

The V-belt evolved from the flat belts which were in general use beforehand. Manufacturers found that “V” profile allowed the belt to sit firmly in the pulley groove, increasing friction and reducing slippage.

The V-belt was found to be more efficient at transmitting torque because of the wedging action. They were much more resistant to stretching capable of lasting tens of thousands of miles if properly tensioned. Each of the above accessories were generally fitted with its own V-belt, meaning that only one belt needs replacing if and when it wore out. To ensure maximum performance and to prevent the possibility of breakdowns and damage to the engine of a classic car, the tension and condition of the V-belt should be checked frequently. If the charge warning light comes on while driving, the V-belt may be broken. The alternator and water pump will then not work properly, so you should stop immediately. Signs of a slipping V-belt include rising engine temperature and possibly a dead battery.

To ensure maximum performance and to prevent the possibility of breakdowns and damage to the engine of a classic car, the tension and condition of the V-belt should be checked frequently. If the charge warning light comes on while driving, the V-belt may be broken. The alternator and water pump will then not work properly, so you should stop immediately. Signs of a slipping V-belt include rising engine temperature and possibly a dead battery.

The V-belt often slips when the generator is under load, for example, when the main headlights, the heated rear window, and other consumers are turned on. The charging indicator light does not come on, even though the battery is never charged.

Wiring unit, brake disc, and water pump

If the water pump does not run at the necessary speed, the engine will overheat. Moreover, the V-belt wears out faster with poor tension: The running surface develops fine cracks.

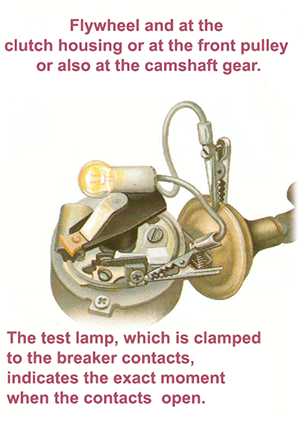

If the V-belt has stretched and is slipping, it can be readjusted using the adjusting mechanism of the alternator.

To adjust the V-belt tension, loosen the clamping nut in the slotted metal rail, insert a crowbar between the engine and the alternator, and push it away from the engine so that the V-belt tightens.

When the time comes to replace a V-belt.

In any event it is always advisable to always carry a suitable replacement V-belt in the vehicle. Even though the vehicle has been out of production for many years, many authorised workshops and the specialised spare parts trade are known to carry a whole range of V-belts for all possible brands.

The V-belt often slips when the generator is under load, for example, when the main headlights, the heated rear window, and other consumers are turned on. The charging indicator light does not come on, even though the battery is never charged.

Wiring unit, brake disc, and water pump

If the water pump does not run at the necessary speed, the engine will overheat. Moreover, the V-belt wears out faster with poor tension: The running surface develops fine cracks.

If the V-belt has stretched and is slipping, it can be readjusted using the adjusting mechanism of the alternator.

To adjust the V-belt tension, loosen the clamping nut in the slotted metal rail, insert a crowbar between the engine and the alternator, and push it away from the engine so that the V-belt tightens.

When the time comes to replace a V-belt.

In any event it is always advisable to always carry a suitable replacement V-belt in the vehicle. Even though the vehicle has been out of production for many years, many authorised workshops and the specialised spare parts trade are known to carry a whole range of V-belts for all possible brands.

It is important to have relevant information on the correct length, the belt profile and, if available. the quality specification.

Recently, so-called flank-open V-belts, which are designated with the abbreviation "FO," have been installed. They are highly durable and therefore recommended.

The old V-belt can usually be removed easily if you loosen the light machine adjustment and attachment in the rear part. The light machine folds down towards the engine, and the V-belt is pulled over the fan wheel.

It is important to have relevant information on the correct length, the belt profile and, if available. the quality specification.

Recently, so-called flank-open V-belts, which are designated with the abbreviation "FO," have been installed. They are highly durable and therefore recommended.

The old V-belt can usually be removed easily if you loosen the light machine adjustment and attachment in the rear part. The light machine folds down towards the engine, and the V-belt is pulled over the fan wheel.

The new V-belt is carefully guided around the upper wheel and first placed on the V-belt pulley of the crankshaft and the alternator. Then one hand grips the lever of the water pump, while the other hand places the V-belt diagonally on the V-belt pulley of the water pump. When the lever is pulled, the V-belt is automatically wound onto the pulley.

The new V-belt is carefully guided around the upper wheel and first placed on the V-belt pulley of the crankshaft and the alternator. Then one hand grips the lever of the water pump, while the other hand places the V-belt diagonally on the V-belt pulley of the water pump. When the lever is pulled, the V-belt is automatically wound onto the pulley.

Under no circumstances should a screwdriver be used with force, so that the V-belt is not overstretched.

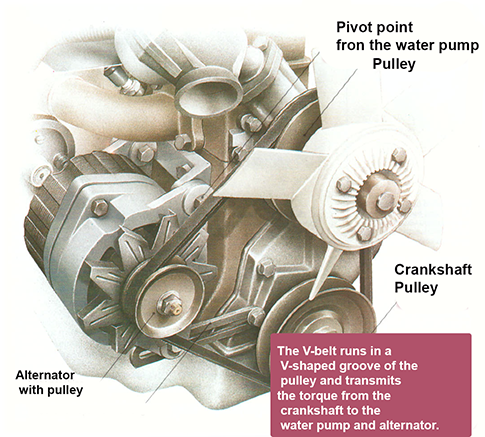

If the vehicle has a viscous coupling, the belt drive cannot be turned with the fan. In this case, a crowfoot wrench is placed on the crankshaft pulley. To finish, the V-belt tension is adjustedTo adjust belt tension. loosening the Mounting Bolts is a requisite. On most classics, the alternator (or dynamo) is on a slotted bracket. In this case all that is required is to loosen the pivot bolt at the bottom and the adjuster bolt/nut on the bracket. Once completed then the position must be adjusted, using a lever against the alternator/dynamo body to move it outward, increasing tension. While holding it in position, the belt deflection should be adjusted carefully

Once that job has been completed, the next stage is tightening all bolts securely, in particular the pivot and adjuster bolts. To ensure that everything is in order, it is advisable to rotate the engine once by hand (using a spanner on the crank pulley nut) to be sure the belt runs evenly in the grooves.

If the need arises to replace a V-Belt, care and attention must be taken to select the correct belt. As previously stated, classic cars often require a specific length/width. Good advice is to bring the old belt (or measure) when buying a replacement. Care should be taken to avoid belts that sit too shallow or too deep in the pulley groove.

If the need arises to replace a V-Belt, care and attention must be taken to select the correct belt. As previously stated, classic cars often require a specific length/width. Good advice is to bring the old belt (or measure) when buying a replacement. Care should be taken to avoid belts that sit too shallow or too deep in the pulley groove.

Take me back to the home page.

ME6