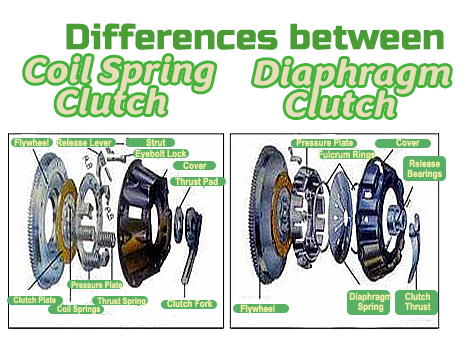

A diaphragm spring clutch is a friction clutch that utilises a diaphragm spring in place of traditional coil springs for the engagement and disengagement of the clutch.

A diaphragm spring clutch is a friction clutch that utilises a diaphragm spring in place of traditional coil springs for the engagement and disengagement of the clutch.

Diaphragm spring clutches gained significant popularity from the Mid -Fifties and Sixties onwards, with demand driven by its enhanced pedal effort & comfort, when compared to conventional coil-spring clutches.

Diaphragm spring clutches gained significant popularity from the Mid -Fifties and Sixties onwards, with demand driven by its enhanced pedal effort & comfort, when compared to conventional coil-spring clutches.

Thanks to their ease of use the demand for manual transmissions saw a significant rise leading to diaphragm spring clutches becoming the favoured option because of their efficiency.

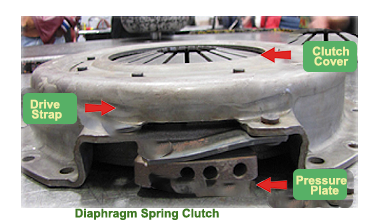

Essential Elements of a Diaphragm Spring Essential

Essential Elements of a Diaphragm Spring Essential

The diaphragm spring clutch like the conventional spring clutch is a circular, almost cone shaped. Its spring features radial fingers that exert pressure on the pressure plate while the pressure plate serves to press the clutch disc against the flywheel, thereby facilitating power gearbox engagement.

The Clutch Disc, often also known as the Friction Disc, is responsible for transferring torque from the engine flywheel to the gearbox.

The flywheel is linked to the engine crankshaft and serves as the surface for clutch disc engagement.

The Release Bearing, sometime known as the Throw-out Bearing, interacts with the diaphragm spring to alleviate clutch pressure upon pressing the pedal.

The Release Bearing, sometime known as the Throw-out Bearing, interacts with the diaphragm spring to alleviate clutch pressure upon pressing the pedal.

The diaphragm spring exerts consistent pressure on the pressure plate when .

the clutch disc is pressed against the flywheel, facilitating the transfer of torque from the engine to the gearbox.

When the clutch pedal is presser the diaphragm will spring inward.

When the clutch pedal is presser the diaphragm will spring inward.

alleviating pressure on the clutch disc, enabling it to separate from the flywheel. allowing the engine to operate independently of the gearbox.

Although automatic transmissions have become standard in the 21st century, rising from around 15% in the Sixties to almost 90% in modern times.

Currently, diaphragm spring clutches are the norm in the majority of manual gearbox vehicles, owing to their benefits compared to traditional coil-spring designs.

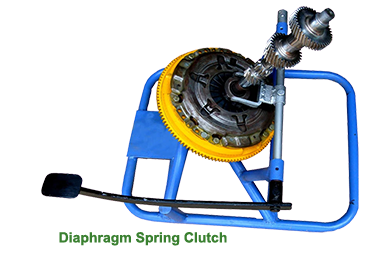

These components are utilised in high-performance and racing applications because of their dependable performance in high-speed situations.

Pioneers of Diaphragm Spring Clutches in the UK and Western Europe were Borg & Beck, a British clutch manufacturer, initiated experiments with diaphragm spring clutch designs as a substitute for coil-spring clutches during the late Forties.

The Fifties saw initial widespread acceptance in Europe, with Citroën leading the way with Traction Avant, with this top-selling model being among the first to incorporate a diaphragm spring clutch, providing a smoother and lighter clutch operation in contrast to traditional coil-spring systems.

The Citroën DS released in 1955, is renowned for its cutting-edge technology across the board, showcasing a semi-automatic gearbox that employed a diaphragm spring clutch for smooth and effortless operation.

The Citroën DS released in 1955, is renowned for its cutting-edge technology across the board, showcasing a semi-automatic gearbox that employed a diaphragm spring clutch for smooth and effortless operation.

The first model to come out of the UK was the multi-million selling Mini. Released in 1959, the innovative Mini, crafted by Alec Issigonis, incorporated a diaphragm clutch within its transverse engine and front-wheel-drive configuration.

Another iconic UK car to feature a diaphragm spring clutch was the Jaguar E-Type which

utilised a diaphragm clutch to ensure smoother gear changes and enhanced durability in high torque situations.

Other Sixties UK icons to come fitted with diaphragm spring clutch were the MGB and the Ford Cortina Series.

By the Eighties, virtually all manual gearbox vehicles from manufacturers such as Ford, Volkswagen, BMW, Peugeot, Renault, and British Leyland adopted diaphragm spring clutches as the standard technology.

The benefits of owning a classic car fitted with a Diaphragm Spring Clutch are as follows.

Reduced Pedal Effort – Necessitates less force to engage than coil spring clutches.

Enhanced Durability – Uniform pressure distribution minimises wear.

pressure is maintained as the clutch experiences wear.

Compact and Lightweight – Contains fewer components than coil-spring designs.

Enhances Performance at Elevated RPMs – Minimises clutch slippage during high-speed scenarios.

On the downside, Diaphragm Spring Clutch are expensive to maintain and more liable to wear out over time much quicker than its conventional counterpart.

On the downside, Diaphragm Spring Clutch are expensive to maintain and more liable to wear out over time much quicker than its conventional counterpart.

Advancements in materials and engineering have led to diaphragm clutches becoming increasingly durable and efficient.

Advancements in materials and engineering have led to diaphragm clutches becoming increasingly durable and efficient.

It remains a common choice in almost all manual gearbox vehicles today, thanks to its efficiency, lighter pedal feel, and reliability.

Performance cars like Porsche, BMW M models, and other high-end sports cars consistently utilise reinforced diaphragm clutches to achieve exceptional torque handling capabilities.

Take me back to the home page.

ME6