Setting up and operating a vehicle maintenance workshop requires putting a number of key elements in place. The first, and still the most important, is the human element. A workshop may have the best in tools and equipment at their disposal but without the people with the skills and initiative to operate them, the workshop’s goals may never be reached.

Setting up and operating a vehicle maintenance workshop requires putting a number of key elements in place. The first, and still the most important, is the human element. A workshop may have the best in tools and equipment at their disposal but without the people with the skills and initiative to operate them, the workshop’s goals may never be reached.

A certain way to keep skilled happy in their work environment is to invest both thought and investment to create an efficient, professional and safe environment. Without that environment, even the most skilled mechanics will sooner or later find their surroundings too much of a challenge to provide reliable, top-notch service.

A certain way to keep skilled happy in their work environment is to invest both thought and investment to create an efficient, professional and safe environment. Without that environment, even the most skilled mechanics will sooner or later find their surroundings too much of a challenge to provide reliable, top-notch service.

The list of the most appropriate fixtures and fittings necessary for a productive workshop is not too long, although it should contain the building blocks to make for a successful car maintenance workshop.

The list of the most appropriate fixtures and fittings necessary for a productive workshop is not too long, although it should contain the building blocks to make for a successful car maintenance workshop.

The first requisite is sturdy workbenches, fundamental to the essence of any workshop, providing a stable platform to enable disassembly, repairs, and inspections of vehicle components being worked on.

The ideal workshop benches should ideally include the following features:

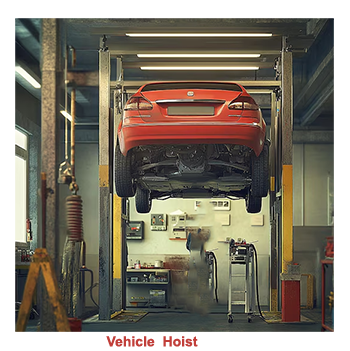

• Steel or hardwood tops designed to endure heavy loads and frequent use. • Implemented vices to ensure secure holding of components. •The design features that will enable a modular workshop layout. Making the best use of floorspace available. Secondly, but not by much, is the presence of at least one hoist that will allow safe access to a vehicle's underbody.

Secondly, but not by much, is the presence of at least one hoist that will allow safe access to a vehicle's underbody.

A factor that is often overlooked is effective lighting in the workshop. Overhead LED lighting systems have become very popular in the last few years, designed to be bright and shadow-free, and certainly more cost effective than fluorescent tubes. Working under improper lighting is not only dangerous but will erode the quality of the work being carried out.

A factor that is often overlooked is effective lighting in the workshop. Overhead LED lighting systems have become very popular in the last few years, designed to be bright and shadow-free, and certainly more cost effective than fluorescent tubes. Working under improper lighting is not only dangerous but will erode the quality of the work being carried out.

- First aid kits should be placed in visible and easily accessible locations.

- Fire extinguishers along with wall-mounted brackets positioned at strategic locations

- Emergency lighting and signage, which encompasses illuminated exit signs.

- Ventilation systems or exhaust extractors designed to eliminate harmful fumes.

These installations are not merely recommended; they are frequently required by health and safety regulations.

These installations are not merely recommended; they are frequently required by health and safety regulations.

Every functional workshop should provide facilities for cleaning and waste disposal.

Appropriate fixtures should ideally include:

• Parts washers designed for effectively degreasing components. • Oil drainage systems and storage tanks intended for the safe handling and removal of waste fluids.

• Shelving and bins utilised for the organised separation of recyclable materials, hazardous waste, and general refuse.

• Dust Extraction and Ventilation Systems designed to improve air quality in the workshop while grinding, sanding or welding operations are taking place.

• Heavy-Duty Tool Cabinets to keep hand and power tools safe when not in use, -preventing unnecessary clutter.

• Parts Storage Racks to ensure that spare parts and consumables are easily accessible- -preventing unnecessary clutter.

Oil drainage systems and storage tanks intended for the safe handling and removal of waste fluids.

• Shelving and bins utilised for the organised separation of recyclable materials, hazardous waste, and general refuse.

• Dust Extraction and Ventilation Systems designed to improve air quality in the workshop while grinding, sanding or welding operations are taking place.

• Heavy-Duty Tool Cabinets to keep hand and power tools safe when not in use, -preventing unnecessary clutter.

• Parts Storage Racks to ensure that spare parts and consumables are easily accessible- -preventing unnecessary clutter.

In any car maintenance workshop irrespective of its size and the volume of work that it handles, should be equipped with fixtures and fittings are those that effectively balance efficiency practicality and safety.

In any car maintenance workshop irrespective of its size and the volume of work that it handles, should be equipped with fixtures and fittings are those that effectively balance efficiency practicality and safety.

Investing in the most suitable fixtures and fittings will significantly boost productivity while simultaneously enhancing safety and fostering customer confidence. A well-equipped workshop serves not just as a place for repairs; it should also function as a professional setting constantly capable of providing reliable, high-quality levels of maintenance.

eq4