Manually operated hand tools remain among the most important part of almost every task done in a workshop involved in the restoration and maintenance of classic old cars. During the golden era when these cars were in production, most of the mechanical and bodywork work was carried out by traditional craftsmen, long before it was considered that a machine carry out any kind of similar procedure.

Manually operated hand tools remain among the most important part of almost every task done in a workshop involved in the restoration and maintenance of classic old cars. During the golden era when these cars were in production, most of the mechanical and bodywork work was carried out by traditional craftsmen, long before it was considered that a machine carry out any kind of similar procedure.

The heritage of these craftsmen, accuracy, mechanical sympathy, and tactile control—are still very important for restoration today. Every variety of tool that can be found in a classic car restoration work shop, ranging from chisels and punches, saws and snips, clamps, files, hammers, pliers, screwdrivers, sockets, spanners, and wrenches, play a different but interchangeable role in keeping things unique and making sure any project, large or small, will be carried out to the highest level.

The heritage of these craftsmen, accuracy, mechanical sympathy, and tactile control—are still very important for restoration today. Every variety of tool that can be found in a classic car restoration work shop, ranging from chisels and punches, saws and snips, clamps, files, hammers, pliers, screwdrivers, sockets, spanners, and wrenches, play a different but interchangeable role in keeping things unique and making sure any project, large or small, will be carried out to the highest level.

Chisels and punches are very important tools, invaluable for tasks that involve aligning, taking apart, and making things. Punches are used to mark drilling spots exactly, make sure bolt holes are lined up during reassembly, and drive rivets or pins without hurting nearby materials. Chisels are great for cutting and separating metal with precision, whether splitting rusted panels, cleaning weld seams, or freeing stuck fasteners.

Applying stress by hand, which makes sure that it happens slowly, a chisel will lower the chance that nearby parts will be damaged or that old steel will crack.

Any classic car restoration and maintenance workshop will always need to have both snips and saws in their range of tools. Hacksaws can be used to cut brackets, exhaust sections, fasteners, and tubing when using power tools would be too strong or dangerous.

Any classic car restoration and maintenance workshop will always need to have both snips and saws in their range of tools. Hacksaws can be used to cut brackets, exhaust sections, fasteners, and tubing when using power tools would be too strong or dangerous.

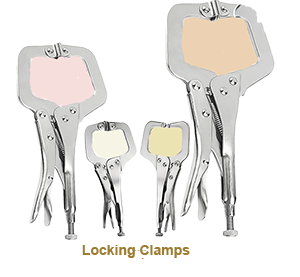

Clamps are often regarded as the unsung heroes of the workshop because they hold parts in place while work is being done. There are al manners of clamps, among them bar clamps, g-clamps, locking clamps and speciality clamps to hold parts on benches while they are being machined or filed, hold brackets while they are being drilled and hold body panels in place while they are being welded.

Clamps are often regarded as the unsung heroes of the workshop because they hold parts in place while work is being done. There are al manners of clamps, among them bar clamps, g-clamps, locking clamps and speciality clamps to hold parts on benches while they are being machined or filed, hold brackets while they are being drilled and hold body panels in place while they are being welded.

When restoring classic cars, clamps that can be used for test fitting and preparing mock-ups because parts may need to be moved and put back together several times before they are ready for final reassembly.

Files that can be hand-controlled are very important finishing tools. Body files are used during metal finishing to smooth out the surfaces of panels and bring out high spots, allowing restorers to create straight panels while using less filler.

Files that can be hand-controlled are very important finishing tools. Body files are used during metal finishing to smooth out the surfaces of panels and bring out high spots, allowing restorers to create straight panels while using less filler.

Maintenance teams use files, flat files and half-round files for the delicate task of cleaning gasket faces, dress welds, adjust brackets and improve fabricated parts. Files have the distinct advantage of being capable of removing excess or waste material slowly and evenly to prevent heat from building up and to keep original parts in good shape. A crucial factor when replacement parts are hard to find or not available.

Maintenance teams use files, flat files and half-round files for the delicate task of cleaning gasket faces, dress welds, adjust brackets and improve fabricated parts. Files have the distinct advantage of being capable of removing excess or waste material slowly and evenly to prevent heat from building up and to keep original parts in good shape. A crucial factor when replacement parts are hard to find or not available.

The often-unsung hammer is one of the most useful tools to have in a classic car restoration and maintenance workshop. Body and bumping hammers are just the tool to reshape panels, remove dents and return them to their original shapes. Planishing and finishing hammers make surfaces smooth enough to almost be ready for paint. Brass and soft-faced hammers are a necessary tool for suspension, steering, and bearing work because they let parts move without breaking. Club or blacksmith hammers, which are heavier, are used for making things and changing their structure. The restorer can feel how the material reacts by using controlled force from each hammer.

The often-unsung hammer is one of the most useful tools to have in a classic car restoration and maintenance workshop. Body and bumping hammers are just the tool to reshape panels, remove dents and return them to their original shapes. Planishing and finishing hammers make surfaces smooth enough to almost be ready for paint. Brass and soft-faced hammers are a necessary tool for suspension, steering, and bearing work because they let parts move without breaking. Club or blacksmith hammers, which are heavier, are used for making things and changing their structure. The restorer can feel how the material reacts by using controlled force from each hammer.

Pliers are capable of carrying out such a variety of important tasks, among them gripping, bending, cutting, and holding. General-purpose and long-nose pliers are used to install wiring, linkages, and springs, while crimping pliers make sure that electrical connections are safe, while cutting pliers cut wire and take off clips. Radiator hose pliers and hose pinch-off tools let the fuel and cooling systems work without having to remove any fluids. When putting an engine back together, specialist pliers such a piston ring or valve shim pliers are invaluable. Because they are both accurate and come in a wide range of sizes, pliers are very useful for solving problems.

Pliers are capable of carrying out such a variety of important tasks, among them gripping, bending, cutting, and holding. General-purpose and long-nose pliers are used to install wiring, linkages, and springs, while crimping pliers make sure that electrical connections are safe, while cutting pliers cut wire and take off clips. Radiator hose pliers and hose pinch-off tools let the fuel and cooling systems work without having to remove any fluids. When putting an engine back together, specialist pliers such a piston ring or valve shim pliers are invaluable. Because they are both accurate and come in a wide range of sizes, pliers are very useful for solving problems.

When using traditional fasteners, manual screwdrivers are a must-have. Flat-bladed screwdrivers are very important because a lot of old cars have slotted screws in their electrical systems, carburettors, and interiors, while hexagonal headed and Phillips screwdrivers will do the job on both new and old replacement parts. Screwdrivers with are angled, offset, and short heads allow access to the tight spots that are common in older vehicles. The increased manual control that manually operated screwdrivers provide prevent soft screw heads, threads, and castings from getting too tight.

When using traditional fasteners, manual screwdrivers are a must-have. Flat-bladed screwdrivers are very important because a lot of old cars have slotted screws in their electrical systems, carburettors, and interiors, while hexagonal headed and Phillips screwdrivers will do the job on both new and old replacement parts. Screwdrivers with are angled, offset, and short heads allow access to the tight spots that are common in older vehicles. The increased manual control that manually operated screwdrivers provide prevent soft screw heads, threads, and castings from getting too tight.

Hand-operated sockets were designed to apply torque in a precise and effective way. When access is limited, twelve-point sockets have been found to be more useful. while. fasteners are new or rusty, six-point sockets will do a better job. Deep and shallow sockets will hold studs of different lengths, and speciality sockets like spark plug, universal joint and pass-through kinds are vital when coping the tricky layouts of classic car engines and chassis. Operators can feel resistance and stop before the threads break by using manual sockets.

Hand-operated sockets were designed to apply torque in a precise and effective way. When access is limited, twelve-point sockets have been found to be more useful. while. fasteners are new or rusty, six-point sockets will do a better job. Deep and shallow sockets will hold studs of different lengths, and speciality sockets like spark plug, universal joint and pass-through kinds are vital when coping the tricky layouts of classic car engines and chassis. Operators can feel resistance and stop before the threads break by using manual sockets.

People who work on classic cars often use open-ended, ring, combination, and adjustable spanners. Flare nut spanners protect fuel and brake line couplings, while stubby and offset spanners let you get into tight spaces. You need both metric and imperial spanners because fastener standards are different. Torque spanners make sure that important parts are tightened correctly, which keeps both safety and authenticity.

People who work on classic cars often use open-ended, ring, combination, and adjustable spanners. Flare nut spanners protect fuel and brake line couplings, while stubby and offset spanners let you get into tight spaces. You need both metric and imperial spanners because fastener standards are different. Torque spanners make sure that important parts are tightened correctly, which keeps both safety and authenticity.

Wrenches complement the use of the spanner's job by making it more useful for specific tasks. Torque wrenches make sure that the engine and suspension are installed correctly. Pipe, chain, and strap wrenches can hold round things like exhausts, filters, and pulleys. For many classic car engines, tuning and adjusting the valves correctly are important maintenance tasks that can be done with distributor and tappet wrenches. Tap ratchets fix broken threads instead of needing to be replaced.

Wrenches complement the use of the spanner's job by making it more useful for specific tasks. Torque wrenches make sure that the engine and suspension are installed correctly. Pipe, chain, and strap wrenches can hold round things like exhausts, filters, and pulleys. For many classic car engines, tuning and adjusting the valves correctly are important maintenance tasks that can be done with distributor and tappet wrenches. Tap ratchets fix broken threads instead of needing to be replaced.

The main benefit of hand tools that you control yourself is that you have more control. Classic cars often have older materials, softer metals, and original parts that are hard to find. With the tactile feedback that hand tools give, the restorer can feel resistance, change the amount of force they use, and avoid permanent damage. They also use the same methods that were used to build the car, following the rules of the time.

All of the tools in each category are necessary for everything from making things and taking them apart to putting them together and making small adjustments. They are still relevant today because they are accurate, flexible, and respectful of the source materials. When used correctly, manually operated hand tools do more than repair broken parts, they also protect the authenticity, craftsmanship, and living history that each classic car stands for.