In any classic car restoration and maintenance workshop, manually operated hammers stand out as essential and highly adaptable tools in the toolkit. Before the advent of hydraulic presses and powered body tools, the assembly, repair, and refinement of vehicles were predominantly accomplished by hand.

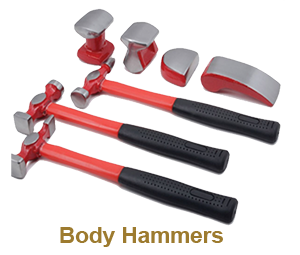

Every type of hammer is designed for a particular function, characterised by its weight, balance, face shape, and material. When used appropriately, manually operated hammers enable the application of controlled force exactly where it is required—crucial for working with aged steel, aluminium, brass, wood, and cast components. Body hammers play a crucial role in classic car bodywork and metal shaping. Body hammers are generally lightweight tools featuring carefully contoured faces that facilitate the movement of sheet metal without causing stretching or tearing. They are utilised alongside dollies to straighten dented panels and restore original shapes. These tools are essential for repairing wings, doors, bonnets, and roof panels, where precise control is necessary.

Body hammers play a crucial role in classic car bodywork and metal shaping. Body hammers are generally lightweight tools featuring carefully contoured faces that facilitate the movement of sheet metal without causing stretching or tearing. They are utilised alongside dollies to straighten dented panels and restore original shapes. These tools are essential for repairing wings, doors, bonnets, and roof panels, where precise control is necessary.

Bumping hammers, which are heavier than finishing hammers, play a crucial role in the early stages of panel repair. Their wide surfaces are employed to swiftly manipulate metal, effectively removing significant dents and reforming warped sections, enabling damaged panels to be realigned before the more detailed shaping and finishing processes commence.

Bumping hammers, which are heavier than finishing hammers, play a crucial role in the early stages of panel repair. Their wide surfaces are employed to swiftly manipulate metal, effectively removing significant dents and reforming warped sections, enabling damaged panels to be realigned before the more detailed shaping and finishing processes commence.

Planishing hammers emerge as essential tools in the final stages of metal finishing. They are lighter and smoother compared to bumping hammers, which makes them particularly effective for refining the surface of a panel after it has been roughly shaped. When utilised properly, planishing hammers refine the metal’s grain structure, eliminate minor imperfections, and ready panels for minimal filler or paint, which is particularly crucial in high-quality restorations.

Planishing hammers emerge as essential tools in the final stages of metal finishing. They are lighter and smoother compared to bumping hammers, which makes them particularly effective for refining the surface of a panel after it has been roughly shaped. When utilised properly, planishing hammers refine the metal’s grain structure, eliminate minor imperfections, and ready panels for minimal filler or paint, which is particularly crucial in high-quality restorations.

Pick hammers are characterised by their pointed end, which contrasts with a flat or rounded face. These tools are employed to elevate low areas in sheet metal by exerting controlled force externally while providing support from the rear. Pick hammers are essential for addressing minor, localised flaws that are difficult to access with larger tools, and they are frequently utilised on curved surfaces like wheel arches, door skins, and roof panels.

Pick hammers are characterised by their pointed end, which contrasts with a flat or rounded face. These tools are employed to elevate low areas in sheet metal by exerting controlled force externally while providing support from the rear. Pick hammers are essential for addressing minor, localised flaws that are difficult to access with larger tools, and they are frequently utilised on curved surfaces like wheel arches, door skins, and roof panels.

Panel hammers serve multiple purposes in shaping and straightening, establishing their importance in restoration workshops. They are especially effective for large flat or gently curved surfaces, like door panels or quarter panels, where uniform shaping across extensive areas is essential.

Panel hammers serve multiple purposes in shaping and straightening, establishing their importance in restoration workshops. They are especially effective for large flat or gently curved surfaces, like door panels or quarter panels, where uniform shaping across extensive areas is essential.

Finish hammers are specifically crafted to minimise marking on metal surfaces. As their name implies, they are utilised in the final stages of panel work, typically following planishing, to eliminate light ripples and enhance surface quality.

Brass hammers are crucial for situations where force needs to be exerted without causing harm to the component being struck. Brass hammers, being softer than steel, effectively absorb much of the impact, which minimises the risk of mushrooming or marking parts. In classic car workshops, it is common to use brass hammers on suspension components.

Brass hammers are crucial for situations where force needs to be exerted without causing harm to the component being struck. Brass hammers, being softer than steel, effectively absorb much of the impact, which minimises the risk of mushrooming or marking parts. In classic car workshops, it is common to use brass hammers on suspension components.

Club hammers, characterised by their short handles and substantial weight, are specifically engineered to provide controlled and forceful strikes. In restoration work, these tools are utilised for driving chisels, straightening heavy brackets, and adjusting chassis components. Their compact design allows for use in confined spaces where larger sledgehammers would not be practical.

Chipping hammers serve a crucial role in dismantling and preparation tasks, effectively removing rust scale, old weld slag, and underbody coatings. Chipping hammers play a crucial role in classic restorations, especially when it comes to stripping chassis rails and undersealed floor pans. Their pointed or chisel-shaped ends enable accurate removal while minimising damage to the underlying metal.

Chipping hammers serve a crucial role in dismantling and preparation tasks, effectively removing rust scale, old weld slag, and underbody coatings. Chipping hammers play a crucial role in classic restorations, especially when it comes to stripping chassis rails and undersealed floor pans. Their pointed or chisel-shaped ends enable accurate removal while minimising damage to the underlying metal.

Grooving hammers are specialised tools designed for creating channels, seams, and precise lines in sheet metal. In classic bodywork, these techniques are frequently employed to replicate original pressed seams, reinforce ribs, or add decorative lines characteristic of vintage vehicles.

Machinists’ hammers play a crucial role in mechanical fitting and assembly tasks, particularly for tapping parts into alignment and effectively using punches and drifts. In a classic car workshop, machinists’ hammers play a crucial role in engine assemblies, gearbox work, brake systems, and suspension components, where precision and control are essential.

The ball pein hammer stands out as a highly versatile tool in any workshop setting. The ball pein hammer, characterised by its flat striking face and rounded pein, is widely utilised in mechanical work. It is particularly effective for driving punches and drifts, aligning components, and seating parts during assembly. The rounded pein is utilised for shaping and peening metal, particularly when original components necessitate precise adjustments instead of outright replacement.

The ball pein hammer stands out as a highly versatile tool in any workshop setting. The ball pein hammer, characterised by its flat striking face and rounded pein, is widely utilised in mechanical work. It is particularly effective for driving punches and drifts, aligning components, and seating parts during assembly. The rounded pein is utilised for shaping and peening metal, particularly when original components necessitate precise adjustments instead of outright replacement.

The blacksmith hammer, heavier and intended for more forceful shaping tasks, is frequently utilised in fabrication work, especially for creating or repairing brackets, chassis components, exhaust hangers, and custom parts that are no longer accessible.

The bumping hammer is essential for bodywork and panel repair. The design facilitates the efficient movement of sheet metal in the initial phases of dent removal. In classic car restoration, bumping hammers serve the purpose of removing large dents and reshaping panels before the finer finishing work commences. This approach minimises the requirement for excessive filler while retaining as much of the original metal as feasible.

The bumping hammer is essential for bodywork and panel repair. The design facilitates the efficient movement of sheet metal in the initial phases of dent removal. In classic car restoration, bumping hammers serve the purpose of removing large dents and reshaping panels before the finer finishing work commences. This approach minimises the requirement for excessive filler while retaining as much of the original metal as feasible.

A riveting hammer is a specialised tool designed for the purpose of forming and setting rivets. Numerous classic vehicles utilise riveted construction for their body panels, frames, and trim. Riveting hammers enable restorers to replicate original assembly techniques, which is crucial for achieving historically accurate and concours-level restorations.

The wide-nose peen hammer is utilised for precise metal shaping across a broader surface area. The wide peen distributes force uniformly, making it well-suited for shaping seams, flanges, and gentle curves in sheet metal. This technique is particularly effective for enhancing panel edges and attaining smooth, factory-like contours.

Manually operated hammers are essential tools in a classic car restoration and maintenance workshop. Each type of hammer plays a unique and essential role, from reshaping body panels and refining surfaces to dismantling assemblies and adjusting mechanical components.

When wielded by a skilled restorer, manually operated hammers stand out as some of the most effective tools for preserving automotive history.