In a classic car restoration and maintenance workshop, manually operated wrenches are among the most heavily relied-upon tools. Classic vehicles were engineered in an era when assembly, servicing, and adjustment were carried out entirely by hand, often using a wide variety of fastener types, thread standards, and materials.

As a result, restorers must work with precision and restraint, meaning that a broad selection of wrench types should be a focal point of any classic car restoration and maintenance workshop to address everything from engine rebuilding and chassis work to fine mechanical adjustment and routine servicing.

Open-ended wrenches should be a fundamental tool in any classic car restoration or maintenance workshop. Their slim jaws allow access to fasteners where clearance is limited, such as carburettor linkages, brake adjusters, fuel fittings, and steering components. Open-ended wrenches are ideal for turning nuts incrementally when there is little swing room.

Featuring an open end and a ring (box) end of the same size, are among the most versatile tools available, combination wrenches with their open end typically used to start or position a fastener, while the ring end provides greater grip for tightening or loosening.

In a classic restoration or maintenance workshop, combination wrenches are used extensively during dismantling and reassembly across engines, suspensions and body fittings.

Heavy-duty ring wrenches were specifically designed for high-torque applications. They fully enclose the fastener, spreading force evenly and reducing the risk of rounding corroded or original nuts and bolts. Heavy-duty ring wrenches are an essential tool when working on chassis bolts, suspension pivots, differential mounts, and engine mountings, especially those that that may not have been disturbed for decades. Offset wrenches feature angled heads that allow access around obstacles.

Classic vehicles often have tightly packed engine bays and limited underbody clearance, making offset wrenches invaluable when working around exhaust systems, steering boxes, and brake components.

Providing increased flexibility when dealing with non-standard or previously modified fasteners, a common factor in classic vehicles with mixed repair histories. Crescent wrenches (adjustable wrenches) have proved themselves to be the tool of choice.

While they lack the precise fit of fixed-size wrenches, crescent wrenches have proved themselves very useful for holding secondary nuts, adjusting large fittings, or working on components where the exact size is uncertain. Skilled use is essential to avoid slippage and fastener damage.

Torque wrenches are critical for safe and accurate assembly. Classic engines, gearboxes, and suspension components often require precise torque values to protect aged threads and castings. Click-type torque wrenches are widely used for general assembly, with their distinctive click providing an audible and tactile signal when the correct torque is reached while dial torque wrenches provide visual confirmation, making them the first choice for precision work, such as engine internals or delicate aluminium components.

Using torque wrenches ensures consistency, reliability, and safety—particularly important in classic vehicles where over-tightening can crack castings or strip threads.

Both slim and offset, distributor wrenches were specifically designed to reach distributor clamp bolts and adjustment nuts. Distributor wrenches are essential tools for such tasks as ignition timing adjustments, a critical routine in maintaining classic carburetted engines.

Tappet wrenches are specialist tools used for valve clearance adjustment. Many classic car engines require their tappets to be set regularly, and these wrenches allow precise adjustment of locknuts without disturbing the setting screw. Accurate valve clearances are vital for engine performance, longevity, and correct period operation.

Designed to work around pipes, castings, and structural elements, obstruction wrenches are particularly useful in confined spaces where standard wrenches cannot be positioned directly, such as behind cylinder heads or near bulkheads.

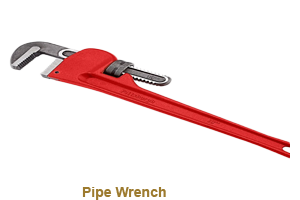

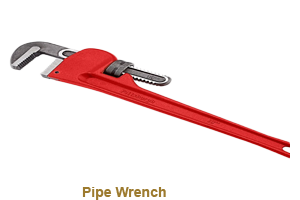

Pipe wrenches were designed for the specific use of gripping round components such as threaded pipes, steering columns, and suspension tubes to release or tighten them. In classic car restoration and maintenance projects, pipe wrenches are often employed when dismantling exhaust systems, coolant pipes, or heavily corroded fittings. Operator care is required, as the serrated jaws of the pipe wrenche can damage surfaces.

Chain wrenches and chain pipe wrenches provide adjustable gripping force around large or awkwardly shaped components, particularly useful for holding cylindrical parts without relying on fixed jaw sizes, such as removing stubborn pulleys, hubs, or large fittings.

Strap wrenches offer a gentler alternative, using fabric or rubber straps, to grip without damaging finished or delicate surfaces. Ideal for polished aluminium components, oil filters, and chromed parts where surface preservation is essential.

Filter wrenches, which also come in chain and strap versions, make for an indispensable tool when it comes to routine servicing. Classic car oil filters are often mounted in awkward positions, while decades of heat cycling can make them difficult to remove. Filter wrenches provide controlled grip without crushing the filter housing.

Designed to fit square or recessed drain plugs, drain plug wrenches are commonly used when servicing classic gearboxes, differentials, and engine sumps. Using the correct tool prevents rounding plugs and damaging housings.

Grip wrenches (locking wrenches) are invaluable for holding damaged fasteners, clamping components temporarily, or providing some extra leverage during dismantling. While not a substitute for correct spanners, grip wrenches are valuable problem-solving tools in restoration work.

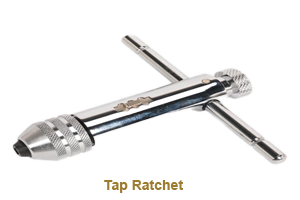

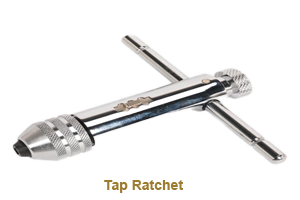

Tap ratchets are used during thread restoration and repair. Classic vehicles often suffer from damaged or corroded threads, and tap ratchets allow controlled cutting or cleaning of threads in confined spaces. This supports component preservation rather than replacement.

Used for wheel removal and installation, providing multiple sizes and good leverage, four-way wheel wrenches are particularly useful during routine maintenance and roadside work.

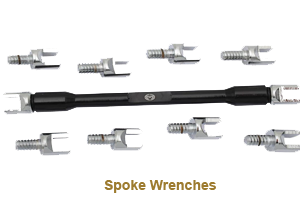

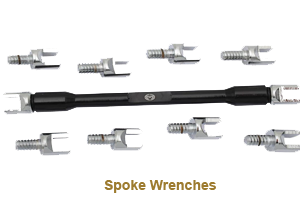

Spoke wrenches are specialist tools used on wire wheels, a feature of many classic British and European cars. Proper spoke tension is essential for wheel strength and trueness, and spoke wrenches allow fine adjustment without damaging nipples or spokes.

Manually operated wrenches form the backbone of a classic car restoration and maintenance workshop. From open-ended and combination wrenches to specialist torque, chain, tappet, and spoke wrenches, each plays a distinct and essential role.

The continued relevance of manually operated wrenches lies in their precision, versatility, and ability to protect original materials and fasteners. In skilled hands, manually operated wrenches will ensure that classic vehicles are restored, maintained, and preserved with the care and authenticity they deserve.

In a classic car restoration and maintenance workshop, manually operated wrenches are among the most heavily relied-upon tools. Classic vehicles were engineered in an era when assembly, servicing, and adjustment were carried out entirely by hand, often using a wide variety of fastener types, thread standards, and materials.

As a result, restorers must work with precision and restraint, meaning that a broad selection of wrench types should be a focal point of any classic car restoration and maintenance workshop to address everything from engine rebuilding and chassis work to fine mechanical adjustment and routine servicing.

In a classic car restoration and maintenance workshop, manually operated wrenches are among the most heavily relied-upon tools. Classic vehicles were engineered in an era when assembly, servicing, and adjustment were carried out entirely by hand, often using a wide variety of fastener types, thread standards, and materials.

As a result, restorers must work with precision and restraint, meaning that a broad selection of wrench types should be a focal point of any classic car restoration and maintenance workshop to address everything from engine rebuilding and chassis work to fine mechanical adjustment and routine servicing.

Open-ended wrenches should be a fundamental tool in any classic car restoration or maintenance workshop. Their slim jaws allow access to fasteners where clearance is limited, such as carburettor linkages, brake adjusters, fuel fittings, and steering components. Open-ended wrenches are ideal for turning nuts incrementally when there is little swing room.

Featuring an open end and a ring (box) end of the same size, are among the most versatile tools available, combination wrenches with their open end typically used to start or position a fastener, while the ring end provides greater grip for tightening or loosening.

In a classic restoration or maintenance workshop, combination wrenches are used extensively during dismantling and reassembly across engines, suspensions and body fittings.

Open-ended wrenches should be a fundamental tool in any classic car restoration or maintenance workshop. Their slim jaws allow access to fasteners where clearance is limited, such as carburettor linkages, brake adjusters, fuel fittings, and steering components. Open-ended wrenches are ideal for turning nuts incrementally when there is little swing room.

Featuring an open end and a ring (box) end of the same size, are among the most versatile tools available, combination wrenches with their open end typically used to start or position a fastener, while the ring end provides greater grip for tightening or loosening.

In a classic restoration or maintenance workshop, combination wrenches are used extensively during dismantling and reassembly across engines, suspensions and body fittings.

Heavy-duty ring wrenches were specifically designed for high-torque applications. They fully enclose the fastener, spreading force evenly and reducing the risk of rounding corroded or original nuts and bolts. Heavy-duty ring wrenches are an essential tool when working on chassis bolts, suspension pivots, differential mounts, and engine mountings, especially those that that may not have been disturbed for decades. Offset wrenches feature angled heads that allow access around obstacles.

Classic vehicles often have tightly packed engine bays and limited underbody clearance, making offset wrenches invaluable when working around exhaust systems, steering boxes, and brake components.

Heavy-duty ring wrenches were specifically designed for high-torque applications. They fully enclose the fastener, spreading force evenly and reducing the risk of rounding corroded or original nuts and bolts. Heavy-duty ring wrenches are an essential tool when working on chassis bolts, suspension pivots, differential mounts, and engine mountings, especially those that that may not have been disturbed for decades. Offset wrenches feature angled heads that allow access around obstacles.

Classic vehicles often have tightly packed engine bays and limited underbody clearance, making offset wrenches invaluable when working around exhaust systems, steering boxes, and brake components.

Providing increased flexibility when dealing with non-standard or previously modified fasteners, a common factor in classic vehicles with mixed repair histories. Crescent wrenches (adjustable wrenches) have proved themselves to be the tool of choice.

While they lack the precise fit of fixed-size wrenches, crescent wrenches have proved themselves very useful for holding secondary nuts, adjusting large fittings, or working on components where the exact size is uncertain. Skilled use is essential to avoid slippage and fastener damage.

Providing increased flexibility when dealing with non-standard or previously modified fasteners, a common factor in classic vehicles with mixed repair histories. Crescent wrenches (adjustable wrenches) have proved themselves to be the tool of choice.

While they lack the precise fit of fixed-size wrenches, crescent wrenches have proved themselves very useful for holding secondary nuts, adjusting large fittings, or working on components where the exact size is uncertain. Skilled use is essential to avoid slippage and fastener damage.

Torque wrenches are critical for safe and accurate assembly. Classic engines, gearboxes, and suspension components often require precise torque values to protect aged threads and castings. Click-type torque wrenches are widely used for general assembly, with their distinctive click providing an audible and tactile signal when the correct torque is reached while dial torque wrenches provide visual confirmation, making them the first choice for precision work, such as engine internals or delicate aluminium components.

Using torque wrenches ensures consistency, reliability, and safety—particularly important in classic vehicles where over-tightening can crack castings or strip threads.

Both slim and offset, distributor wrenches were specifically designed to reach distributor clamp bolts and adjustment nuts. Distributor wrenches are essential tools for such tasks as ignition timing adjustments, a critical routine in maintaining classic carburetted engines.

Torque wrenches are critical for safe and accurate assembly. Classic engines, gearboxes, and suspension components often require precise torque values to protect aged threads and castings. Click-type torque wrenches are widely used for general assembly, with their distinctive click providing an audible and tactile signal when the correct torque is reached while dial torque wrenches provide visual confirmation, making them the first choice for precision work, such as engine internals or delicate aluminium components.

Using torque wrenches ensures consistency, reliability, and safety—particularly important in classic vehicles where over-tightening can crack castings or strip threads.

Both slim and offset, distributor wrenches were specifically designed to reach distributor clamp bolts and adjustment nuts. Distributor wrenches are essential tools for such tasks as ignition timing adjustments, a critical routine in maintaining classic carburetted engines.

Tappet wrenches are specialist tools used for valve clearance adjustment. Many classic car engines require their tappets to be set regularly, and these wrenches allow precise adjustment of locknuts without disturbing the setting screw. Accurate valve clearances are vital for engine performance, longevity, and correct period operation.

Designed to work around pipes, castings, and structural elements, obstruction wrenches are particularly useful in confined spaces where standard wrenches cannot be positioned directly, such as behind cylinder heads or near bulkheads.

Tappet wrenches are specialist tools used for valve clearance adjustment. Many classic car engines require their tappets to be set regularly, and these wrenches allow precise adjustment of locknuts without disturbing the setting screw. Accurate valve clearances are vital for engine performance, longevity, and correct period operation.

Designed to work around pipes, castings, and structural elements, obstruction wrenches are particularly useful in confined spaces where standard wrenches cannot be positioned directly, such as behind cylinder heads or near bulkheads.

Pipe wrenches were designed for the specific use of gripping round components such as threaded pipes, steering columns, and suspension tubes to release or tighten them. In classic car restoration and maintenance projects, pipe wrenches are often employed when dismantling exhaust systems, coolant pipes, or heavily corroded fittings. Operator care is required, as the serrated jaws of the pipe wrenche can damage surfaces.

Chain wrenches and chain pipe wrenches provide adjustable gripping force around large or awkwardly shaped components, particularly useful for holding cylindrical parts without relying on fixed jaw sizes, such as removing stubborn pulleys, hubs, or large fittings.

Pipe wrenches were designed for the specific use of gripping round components such as threaded pipes, steering columns, and suspension tubes to release or tighten them. In classic car restoration and maintenance projects, pipe wrenches are often employed when dismantling exhaust systems, coolant pipes, or heavily corroded fittings. Operator care is required, as the serrated jaws of the pipe wrenche can damage surfaces.

Chain wrenches and chain pipe wrenches provide adjustable gripping force around large or awkwardly shaped components, particularly useful for holding cylindrical parts without relying on fixed jaw sizes, such as removing stubborn pulleys, hubs, or large fittings.

Strap wrenches offer a gentler alternative, using fabric or rubber straps, to grip without damaging finished or delicate surfaces. Ideal for polished aluminium components, oil filters, and chromed parts where surface preservation is essential.

Strap wrenches offer a gentler alternative, using fabric or rubber straps, to grip without damaging finished or delicate surfaces. Ideal for polished aluminium components, oil filters, and chromed parts where surface preservation is essential.

Filter wrenches, which also come in chain and strap versions, make for an indispensable tool when it comes to routine servicing. Classic car oil filters are often mounted in awkward positions, while decades of heat cycling can make them difficult to remove. Filter wrenches provide controlled grip without crushing the filter housing.

Designed to fit square or recessed drain plugs, drain plug wrenches are commonly used when servicing classic gearboxes, differentials, and engine sumps. Using the correct tool prevents rounding plugs and damaging housings.

Grip wrenches (locking wrenches) are invaluable for holding damaged fasteners, clamping components temporarily, or providing some extra leverage during dismantling. While not a substitute for correct spanners, grip wrenches are valuable problem-solving tools in restoration work.

Filter wrenches, which also come in chain and strap versions, make for an indispensable tool when it comes to routine servicing. Classic car oil filters are often mounted in awkward positions, while decades of heat cycling can make them difficult to remove. Filter wrenches provide controlled grip without crushing the filter housing.

Designed to fit square or recessed drain plugs, drain plug wrenches are commonly used when servicing classic gearboxes, differentials, and engine sumps. Using the correct tool prevents rounding plugs and damaging housings.

Grip wrenches (locking wrenches) are invaluable for holding damaged fasteners, clamping components temporarily, or providing some extra leverage during dismantling. While not a substitute for correct spanners, grip wrenches are valuable problem-solving tools in restoration work.

Tap ratchets are used during thread restoration and repair. Classic vehicles often suffer from damaged or corroded threads, and tap ratchets allow controlled cutting or cleaning of threads in confined spaces. This supports component preservation rather than replacement.

Used for wheel removal and installation, providing multiple sizes and good leverage, four-way wheel wrenches are particularly useful during routine maintenance and roadside work.

Tap ratchets are used during thread restoration and repair. Classic vehicles often suffer from damaged or corroded threads, and tap ratchets allow controlled cutting or cleaning of threads in confined spaces. This supports component preservation rather than replacement.

Used for wheel removal and installation, providing multiple sizes and good leverage, four-way wheel wrenches are particularly useful during routine maintenance and roadside work.

Spoke wrenches are specialist tools used on wire wheels, a feature of many classic British and European cars. Proper spoke tension is essential for wheel strength and trueness, and spoke wrenches allow fine adjustment without damaging nipples or spokes.

Manually operated wrenches form the backbone of a classic car restoration and maintenance workshop. From open-ended and combination wrenches to specialist torque, chain, tappet, and spoke wrenches, each plays a distinct and essential role.

The continued relevance of manually operated wrenches lies in their precision, versatility, and ability to protect original materials and fasteners. In skilled hands, manually operated wrenches will ensure that classic vehicles are restored, maintained, and preserved with the care and authenticity they deserve.

Spoke wrenches are specialist tools used on wire wheels, a feature of many classic British and European cars. Proper spoke tension is essential for wheel strength and trueness, and spoke wrenches allow fine adjustment without damaging nipples or spokes.

Manually operated wrenches form the backbone of a classic car restoration and maintenance workshop. From open-ended and combination wrenches to specialist torque, chain, tappet, and spoke wrenches, each plays a distinct and essential role.

The continued relevance of manually operated wrenches lies in their precision, versatility, and ability to protect original materials and fasteners. In skilled hands, manually operated wrenches will ensure that classic vehicles are restored, maintained, and preserved with the care and authenticity they deserve.