Lubrication systems are fundamental in a classic car restoration to ensure safe operation and longevity of any vehicle. Managing these fluids efficiently, cleanly and safely is essential not only for mechanical reliability but also for environmental protection and workplace safety.

In recent times the development of purpose-designed fluid handling systems has allowed restorers and maintainer to work methodically while reducing waste while maintaining consistent service standards across long-term projects.

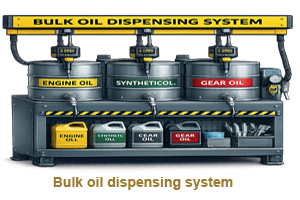

A bulk oil dispensing system provides a centralised and organised way to store and dispense engine oils, gearbox oils, and hydraulic fluids.

A bulk oil dispensing system provides a centralised and organised way to store and dispense engine oils, gearbox oils, and hydraulic fluids.

Classic cars usually require different oil grades from that used in modern vehicles. Having an in-house bulk storage and delivery system in place will allow multiple oils to be stored separately as long as they are clearly labelled.

The ability to dispense measured quantities of oil will, in the long term, reduce waste and contamination while ensuring engines and transmissions receive the correct lubricants, a factor which is critical for protecting older designs with specific lubrication requirements.

The ability to dispense measured quantities of oil will, in the long term, reduce waste and contamination while ensuring engines and transmissions receive the correct lubricants, a factor which is critical for protecting older designs with specific lubrication requirements.

Any form of fuel handling demands special attention due to fire risk and contamination concerns. A dedicated fuel handling and storage cabinet provides secure, ventilated storage for petrol, diesel, and additives. These cabinets reduce the risk of leaks, vapour build-up, and accidental ignition while keeping fuels clearly segregated and accessible. In restoration work, where fuel systems may be drained and refilled repeatedly, safe storage is essential.

Any form of fuel handling demands special attention due to fire risk and contamination concerns. A dedicated fuel handling and storage cabinet provides secure, ventilated storage for petrol, diesel, and additives. These cabinets reduce the risk of leaks, vapour build-up, and accidental ignition while keeping fuels clearly segregated and accessible. In restoration work, where fuel systems may be drained and refilled repeatedly, safe storage is essential.

The correct management of waste fluids responsibly is not only an ethical requirement but a legal one, meaning that every workshop must have a waste oil recovery tank in or near site to provide safe containment of the used oils drained during servicing and restoration. Proper storage prevents spills, contamination, and environmental harm, while also simplifying collection and disposal by licensed contractors.

Increasingly, some of the larger workshops have begun to adopt a fluid recycling system to reduce waste and operating costs. Recycling systems can filter and recondition certain fluids which can be reused for cleaning or non-critical applications. Recycling waste fluids reduces disposal volumes and supports sustainable workshop practices, an important consideration for long-term operations.

Increasingly, some of the larger workshops have begun to adopt a fluid recycling system to reduce waste and operating costs. Recycling systems can filter and recondition certain fluids which can be reused for cleaning or non-critical applications. Recycling waste fluids reduces disposal volumes and supports sustainable workshop practices, an important consideration for long-term operations.

Accidental spills are an ever-present risk when handling oils, fuels, and coolants, making spill containment stations essential by instantly providing absorbents, barriers and disposal materials to deal with leaks quickly and effectively. Rapid spill response will protect workshop floors, prevent slip hazards, and minimise environmental impact.

From a workflow perspective, well-designed fluid systems save time and improve cleanliness. Technicians can access oils, grease, coolant, and fuel efficiently, allowing mechanical work to progress smoothly without interruptions. Clean, controlled fluid handling also enhances assembly and inspection quality, as components remain free from accidental contamination.

eq4

Complementing oil systems is the grease distribution system, particularly valuable in classic car restoration and maintenance workshops. Many classic cars need to have regular greasing, particularly on suspension joints, steering components and driveline parts. Having a central grease system on hand delivering clean, consistent grease to multiple work bays will not only improve efficiency but also ensure that all lubrication points are serviced thoroughly without the need to rely on manual handling of cartridges.

Complementing oil systems is the grease distribution system, particularly valuable in classic car restoration and maintenance workshops. Many classic cars need to have regular greasing, particularly on suspension joints, steering components and driveline parts. Having a central grease system on hand delivering clean, consistent grease to multiple work bays will not only improve efficiency but also ensure that all lubrication points are serviced thoroughly without the need to rely on manual handling of cartridges.