Equipment that was designed and produced to be the centre of a metalworking and fabrication department will play a major role in any classic car restoration and maintenance workshop.

Equipment that was designed and produced to be the centre of a metalworking and fabrication department will play a major role in any classic car restoration and maintenance workshop. Cars that were produced during the Nineteen Fifties and Sixties will inevitably suffer from some form of corrosion, accident damage or simple metal fatigue (or all of them together.)

Because of their age, replacement panels or components for this vehicle are often unavailable or prohibitively expensive. Having the ability to manufacture accurate repair sections and bespoke parts in-house allows restorers to preserve originality, control quality, and work efficiently across long-term projects.

A sheet metal guillotine is one of the most fundamental tools for fabrication work. It allows clean, straight, and repeatable cuts in sheet steel or aluminium, providing accurately sized blanks for panels, brackets, and reinforcement sections. Compared with hand cutting or abrasive methods, a guillotine produces minimal distortion and requires little finishing, which is especially important when working with thin classic-era body panels.

A sheet metal guillotine is one of the most fundamental tools for fabrication work. It allows clean, straight, and repeatable cuts in sheet steel or aluminium, providing accurately sized blanks for panels, brackets, and reinforcement sections. Compared with hand cutting or abrasive methods, a guillotine produces minimal distortion and requires little finishing, which is especially important when working with thin classic-era body panels.

Once it has been cut, metal often needs to be formed very precisely and this where the box and pan brake (folding machine) is called into action. Essential for creating crisp bends and flanges, the box and pan brake is invaluable for battery trays, fabricating sills, floor sections, and inner wings. The adjustable fingers of a box and pan brake allow for the fabrication of the most complex of shapes, replicating original factory pressings while maintaining structural strength.

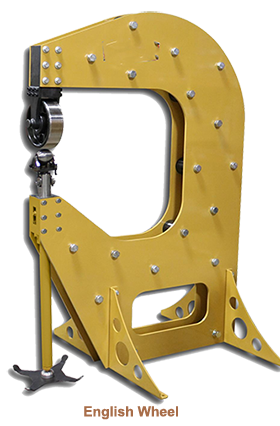

For curved and compound surfaces, the English wheel is unmatched. Classic cars frequently feature flowing wings, roofs, and body panels that cannot be produced using simple folding methods. The English wheel allows metal to be stretched and smoothed gradually, creating subtle curves with excellent surface finish. This capability is particularly important when repairing visible exterior panels where authenticity and appearance are paramount.

For curved and compound surfaces, the English wheel is unmatched. Classic cars frequently feature flowing wings, roofs, and body panels that cannot be produced using simple folding methods. The English wheel allows metal to be stretched and smoothed gradually, creating subtle curves with excellent surface finish. This capability is particularly important when repairing visible exterior panels where authenticity and appearance are paramount.

If tighter shaping and edge refinement is called for, then it’s time call on the shrinker / stretcher which can be either floor or stand mounted. The shrinker / stretcher machine’s role is to allow controlled shrinking or stretching of metal flanges, making it a lot easier for the metal fabricator to form curved edges, wheel arches, and window surrounds without the need to either cut or weld. Shrinker/stretchers dramatically reduce fabrication time and help maintain panel integrity, making them indispensable for precision bodywork.

If tighter shaping and edge refinement is called for, then it’s time call on the shrinker / stretcher which can be either floor or stand mounted. The shrinker / stretcher machine’s role is to allow controlled shrinking or stretching of metal flanges, making it a lot easier for the metal fabricator to form curved edges, wheel arches, and window surrounds without the need to either cut or weld. Shrinker/stretchers dramatically reduce fabrication time and help maintain panel integrity, making them indispensable for precision bodywork.

Slip rollers are another handy piece of equipment to have in a metal working and fabrication workshop/department, especially when cylindrical shapes and gentle curves need to be produced. Ideal for forming fuel tank sections, exhaust heat shields, curved repair panels, and rolled edges, slip rollers will consistently provide consistent curvature and repeatability, essential when fabricating matched components or symmetrical parts.

Apart from body panels, classic car restoration and maintenance workshops will often need to manufacture or refurbish mechanical components, and this is where machine tools become vital. A metal lathe in the workshop will allow accurate turning of bushes, shafts, fasteners and spacers among many other crucial parts that may no longer be available. Lathes enable metal fabricators to achieve precise tolerances, ensuring proper fit and longevity of mechanical assemblies.

Apart from body panels, classic car restoration and maintenance workshops will often need to manufacture or refurbish mechanical components, and this is where machine tools become vital. A metal lathe in the workshop will allow accurate turning of bushes, shafts, fasteners and spacers among many other crucial parts that may no longer be available. Lathes enable metal fabricators to achieve precise tolerances, ensuring proper fit and longevity of mechanical assemblies.

Complementing the metal lathe is the vertical milling machine, whose role it is to provide versatility for such tasks as facing, drilling, profiling and slotting metal parts. Milling machines are invaluable for fabricating brackets, modifying components, and restoring worn mating surfaces. In a restoration context, they allow careful adaptation of parts without compromising structural integrity.

Complementing the metal lathe is the vertical milling machine, whose role it is to provide versatility for such tasks as facing, drilling, profiling and slotting metal parts. Milling machines are invaluable for fabricating brackets, modifying components, and restoring worn mating surfaces. In a restoration context, they allow careful adaptation of parts without compromising structural integrity.

The pedestal drill / pillar drill is a workshop staple, offering accurate, perpendicular drilling with controlled speed and depth. Pedestal drills have consistently been proven to improve accuracy and safety, particularly when drilling hardened metals or for drilling repetitive hole patterns in brackets and panels.

The pedestal drill / pillar drill is a workshop staple, offering accurate, perpendicular drilling with controlled speed and depth. Pedestal drills have consistently been proven to improve accuracy and safety, particularly when drilling hardened metals or for drilling repetitive hole patterns in brackets and panels.

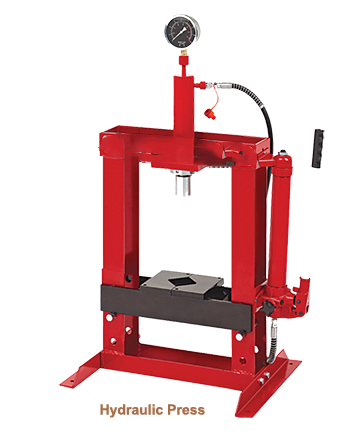

The hydraulic press is called for heavier pressing and forming tasks. making it an essential piece of equipment for installing bearings, bushes, and studs, as well as straightening bent components. In classic car work, where parts may be irreplaceable, the controlled force of a hydraulic press reduces the risk of damage compared with hammering or improvised methods.

Cutting stock and sections efficiently requires dedicated saws. A metal band saw provides clean, accurate cuts in bar stock, tubing, and profiles with minimal waste, making it ideal for fabrication work. For precision cutting, the cold cut saw offers burr-free, square cuts with minimal heat input, preserving material properties and improving safety.

In conclusion, metalworking and fabrication department is often only as good as its equipment and the people who have been retained to operate it. If the combination is right, a classic car restoration and maintenance workshop will be self-sufficient, precise and capable of producing authentic work to a very high standard.

eq4