Sanding, surface preparation, and rust control are listed among the most critical stages in classic car restoration. The quality and longevity of any repair, paint finish, or structural reinforcement depends on how thoroughly corrosion, old coatings, and contaminants are removed beforehand. Dedicated sanding and rust control equipment allows restorers to work methodically, safely, and accurately while preserving as much original material as possible—an essential principle in historic vehicle work.

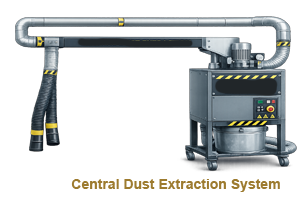

At the foundation of clean preparation work is the central dust extraction system. Sanding, grinding, and filler shaping generate fine dust that can contaminate paintwork, damage machinery, and pose serious health risks.

At the foundation of clean preparation work is the central dust extraction system. Sanding, grinding, and filler shaping generate fine dust that can contaminate paintwork, damage machinery, and pose serious health risks.

The role of the central extraction system is to remove airborne particles as they are generated, allowing for and maintaining clean air levels throughout the workshop, a process that not only protects the health of personnel but also ensures that prepared surfaces remain uncontaminated.

Closely linked to the dust extraction process are vacuum-assisted sanding stations, that combine sanding tools with integrated dust collection, capturing particles directly at the sanding pad. Vacuum-assisted sanding improves reduces clean-up time, visibility of foreign bodies on work surfaces while generating a more uniform scratch pattern.

In classic car restoration, where thin panels and hand-formed surfaces are more common, this level of control helps prevent over-sanding and heat build-up.

A media blasting cabinet is an essential tool, especially geared to removing component-level rust and paint. Enclosed cabinets allow for the controlled blasting of small parts such as brackets, fasteners, suspension components and wheels. By containing abrasive media and dust, cabinets provide consistent results while minimising mess and material loss, especially valuable when cleaning rare and delicate or irreplaceable parts that require gentle but thorough preparation.

A media blasting cabinet is an essential tool, especially geared to removing component-level rust and paint. Enclosed cabinets allow for the controlled blasting of small parts such as brackets, fasteners, suspension components and wheels. By containing abrasive media and dust, cabinets provide consistent results while minimising mess and material loss, especially valuable when cleaning rare and delicate or irreplaceable parts that require gentle but thorough preparation.

For larger components and body shells that often require more powerful solutions, the pressure blasting booth provides a dedicated environment. Pressure blasting booths allow axles, chassis, body panels and even entire subframes to be stripped efficiently under controlled conditions.

For larger components and body shells that often require more powerful solutions, the pressure blasting booth provides a dedicated environment. Pressure blasting booths allow axles, chassis, body panels and even entire subframes to be stripped efficiently under controlled conditions.

Proper ventilation is vital around media recovery systems ensuring high levels of safety and repeatability, making them suitable for the largest-scale restoration projects.

Where preservation of delicate materials is a priority, a soda blasting system using sodium bicarbonate as a soft abrasive, can be called in. This combination makes it an ideal solution for removing paint and light corrosion without running the risk of damaging underlying metal, glass or rubber moulding, Soda blasting is particularly useful on thin body panels, aluminium components, and areas with complex seams where aggressive media could cause distortion.

Where preservation of delicate materials is a priority, a soda blasting system using sodium bicarbonate as a soft abrasive, can be called in. This combination makes it an ideal solution for removing paint and light corrosion without running the risk of damaging underlying metal, glass or rubber moulding, Soda blasting is particularly useful on thin body panels, aluminium components, and areas with complex seams where aggressive media could cause distortion.

An even more specialised solution is the dry ice blasting unit. Dry ice blasting removes coatings and contaminants through thermal shock rather than abrasion, leaving no secondary waste media, making for an excellent solution for cleaning assemblies, engine bays and interiors where disassembly is not an option. Dry ice blasting has the distinct advantage of allowing gentle cleaning while preserving original finishes and markings.

Chemicals have always played a significant role in rust control. The innovation of rust treatment tanks (chemical dip systems) allows for the complete immersion of panels or components to remove rust, paint and sealants from inaccessible cavities.

When properly managed, rust treatment tanks provide a thorough foundation for long-term rust protection.

When properly managed, rust treatment tanks provide a thorough foundation for long-term rust protection.

Beyond the many individual techniques available, the principal advantage of comprehensive sanding and rust control equipment lies in choice and control. The varying materials used in the process; levels of rust corrosion levels and restoration goals will all require different approaches. Having access to multiple systems allows restorers and maintainers to select the least aggressive method that achieves the desired result, balancing efficiency with preservation.

By investing in the right equipment, restoration and maintenance workshops can provide protection for original materials, improving finish quality, while extending the life of a classic car for decades into the future.

72%

eq4