Any aspiring classic car restoration and maintenance workshop would have the best and most efficient equipment at their disposal to ply their trade to the highest level. In most cases restrictions of either budget or space prevent this from becoming a reality.

My classic car info has taken it up ourselves to compile, what we believe to be an accurate analysis of the most essential key categories of equipment that a classic car restoration and maintenance workshop should have (or at least have access to) to meet the demands of a comprehensive and professional classic car restoration of maintenance workshop.

A well-equipped classic car restoration and maintenance workshop must balance traditional craftsmanship with modern efficiency, safety, and reliability. Unlike general automotive garages, restoration workshops deal with fragile materials, obsolete designs, and labour-intensive processes that demand specialist equipment across many disciplines.

The first stage in any classic car restoration or maintenance project is to carry out a thorough appraisal of the vehicle both from above and below. That’s why having vehicle lifting and support equipment is almost a must, forming the foundation of safe and effective inspection and underbody work.

The first stage in any classic car restoration or maintenance project is to carry out a thorough appraisal of the vehicle both from above and below. That’s why having vehicle lifting and support equipment is almost a must, forming the foundation of safe and effective inspection and underbody work.

Available as either two-post or four-post, a vehicle lift allows the most efficient full underbody access for exhaust, mechanical and structural inspection and repairs. If the workshop budget won’t stretch that far, low-rise scissor lifts are available, especially here ceiling height is limited. Supplementary equipment such as axle stands, wheel dollies, transmission jacks, and engine support beams are also less expensive nut with their limitations, while ensuring vehicles and components can be safely supported. Although it is recommended that they be used only during partial disassembly or alignment work.

Having a modern electrical and power infrastructure in place underpins all modern workshop activity, supplying adequate single-phase and, if possible, three-phase supplies to support such power-hungry equipment as compressors machinery and welding equipment. When setting up an electrical and power infrastructure, care should be taken to ensure that well-planned socket placement, cable management, task lighting, and emergency power isolation has been taken to improve safety and workflow. Backup power or surge protection is also advisable for sensitive equipment.

Having a modern electrical and power infrastructure in place underpins all modern workshop activity, supplying adequate single-phase and, if possible, three-phase supplies to support such power-hungry equipment as compressors machinery and welding equipment. When setting up an electrical and power infrastructure, care should be taken to ensure that well-planned socket placement, cable management, task lighting, and emergency power isolation has been taken to improve safety and workflow. Backup power or surge protection is also advisable for sensitive equipment.

A compressed air system is regarded as being central to many workshop operations. This includes a suitably sized compressor, air dryer, filtration system, pressure regulators, and a hard-piped distribution network. Compressed air supports a wide range of pneumatic tools used in assembly, cleaning, cutting, sanding, painting, making reliability and clean, dry air essential.

A compressed air system is regarded as being central to many workshop operations. This includes a suitably sized compressor, air dryer, filtration system, pressure regulators, and a hard-piped distribution network. Compressed air supports a wide range of pneumatic tools used in assembly, cleaning, cutting, sanding, painting, making reliability and clean, dry air essential.

Indispensable for workshop that is involved in structural and body repairs, welding and fabrication equipment in particular MIG welders, commonly used for panel replacement and chassis repairs, or TIG welders that offer precision for thin steel and aluminium components. Spot welders replicate factory joining methods, and plasma cutters assist with accurate panel removal. Welding benches, clamps, and fume extraction systems complete this category.

Closely related is Metalworking and Fabrication Equipment. Bench grinders, drill presses, sheet metal brakes, shrinkers and stretchers, English wheels, bead rollers, and metal saws enable the fabrication of repair sections and bespoke panels. Tools that are vital when replacement panels are unavailable or require modification for authenticity.

Closely related is Metalworking and Fabrication Equipment. Bench grinders, drill presses, sheet metal brakes, shrinkers and stretchers, English wheels, bead rollers, and metal saws enable the fabrication of repair sections and bespoke panels. Tools that are vital when replacement panels are unavailable or require modification for authenticity.

Cleanliness means efficiency in a modern classic car restoration and maintenance workshop, an any investment in cleaning, degreasing and preparation equipment will ensure parts and components are rebuilt on a clean foundation.

Equipment such as parts washers, ultrasonic cleaners, steam cleaners, and solvent tanks remove decades of contamination, while pressure washers and underbody cleaning systems play their part in preparing chassis and suspension components for inspection and coating. For workshops that focus on mechanical restoration and maintenance, having access to cutting edge engine and mechanical workshop equipment is essential. Equipment that includes engine stands, hoists, valve grinding equipment, torque tools, measuring instruments and even a well-planned work bench support engine rebuilding and drivetrain work. Hydraulic presses, bearing pullers, and gearbox stands will allow safe handling of heavy or tightly fitted components.

For workshops that focus on mechanical restoration and maintenance, having access to cutting edge engine and mechanical workshop equipment is essential. Equipment that includes engine stands, hoists, valve grinding equipment, torque tools, measuring instruments and even a well-planned work bench support engine rebuilding and drivetrain work. Hydraulic presses, bearing pullers, and gearbox stands will allow safe handling of heavy or tightly fitted components.

Not every classic car restoration or maintenance workshop handles their own bodywork, paint and finishing equipment, although the importance of top-class bodywork and painting cannot be emphasized enough as it defines the final appearance of the restored vehicle.

Running an efficient bodywork and paint shop not only requires a lot of experience but also a considerable financial investment, including spray booths or enclosed paint areas, extraction systems, spray guns, infrared curing lamps, and paint mixing stations. Proper ventilation and temperature control are critical to achieving high-quality, durable finishes.

Running an efficient bodywork and paint shop not only requires a lot of experience but also a considerable financial investment, including spray booths or enclosed paint areas, extraction systems, spray guns, infrared curing lamps, and paint mixing stations. Proper ventilation and temperature control are critical to achieving high-quality, durable finishes.

Tyre, wheel and suspension equipment enables any workshop to offer customer service at a high level. Equipment required include alignment tools, tyre changers, spring compressors and wheel balancers, all of which support suspension rebuilding and wheel refurbishment, particularly important for vehicles with period-correct wheels and suspension geometries.

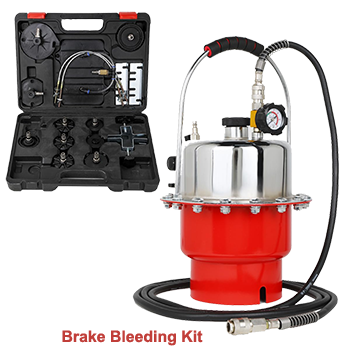

Efficient handling of liquids relies on fuel, cooling and fluid handling systems. Fuel drainers, coolant refill tools, oil dispensers, brake bleeding equipment, and fluid storage systems improve cleanliness and accuracy while reducing environmental risk.

Exhaust and emissions equipment supports fabrication and testing. Exhaust welders, pipe benders, and smoke or gas analysers help fabricate and assess exhaust systems, even where historic vehicles are exempt from modern emissions standards.

Exhaust and emissions equipment supports fabrication and testing. Exhaust welders, pipe benders, and smoke or gas analysers help fabricate and assess exhaust systems, even where historic vehicles are exempt from modern emissions standards.

Modern maintenance and restoration increasingly depend on electrical and diagnostic equipment. battery chargers, diagnostic testers, multimeters, oscilloscopes and wiring tools, will play a very important part in fault-finding, rewiring, and electrical system refurbishment, especially on later classics.

Having the best safety, environmental and compliance equipment in a classic car maintenance and restoration workshop is non-negotiable. Fire extinguishers, fume extraction, spill kits, waste fluid containment and proper waste and fuel disposal systems protect both staff and the environment while ensuring regulatory compliance.

Having the best safety, environmental and compliance equipment in a classic car maintenance and restoration workshop is non-negotiable. Fire extinguishers, fume extraction, spill kits, waste fluid containment and proper waste and fuel disposal systems protect both staff and the environment while ensuring regulatory compliance.

Finally, investing in comfort, workflow and support infrastructure has been proven to enhance productivity in the workplace. That means enhanced heating, ventilation, fans, sound insulation and even computer workstations will make for a clear workflow layout that will reduce fatigue and improve job quality, especially during lengthy restoration or maintenance projects.

eq4